Gelatin Empty Hard Capsule

Description Details

Customized Pharmaceutical Gelatin Empty Capsule

Made from gelatin or other suitable material and filled with a drug(s) to produce a unit dosage

Yasin Could Supply

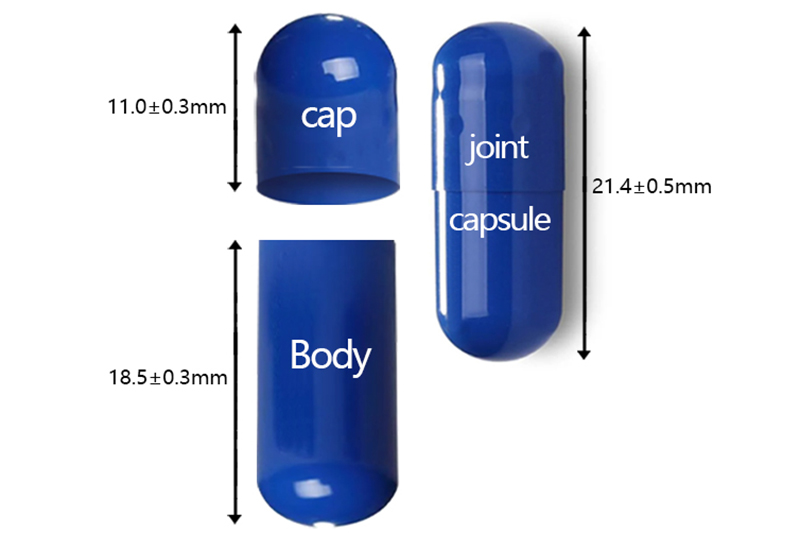

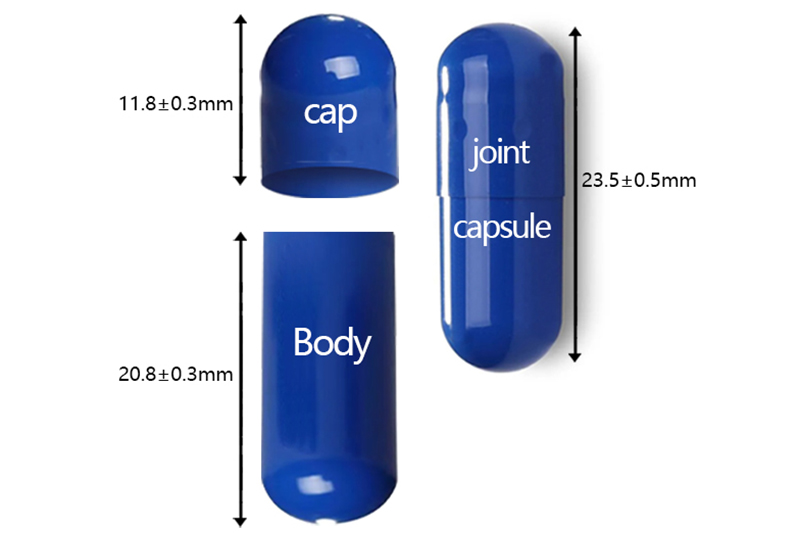

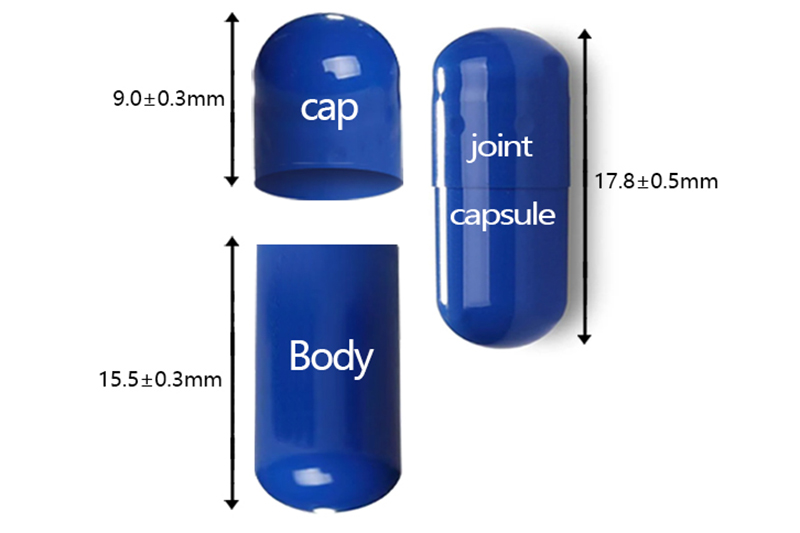

| Empty Hard Gelatin Capsule Shells | ||||||

| Size | 00# | 0# | 1# | 2# | 3# | 4# |

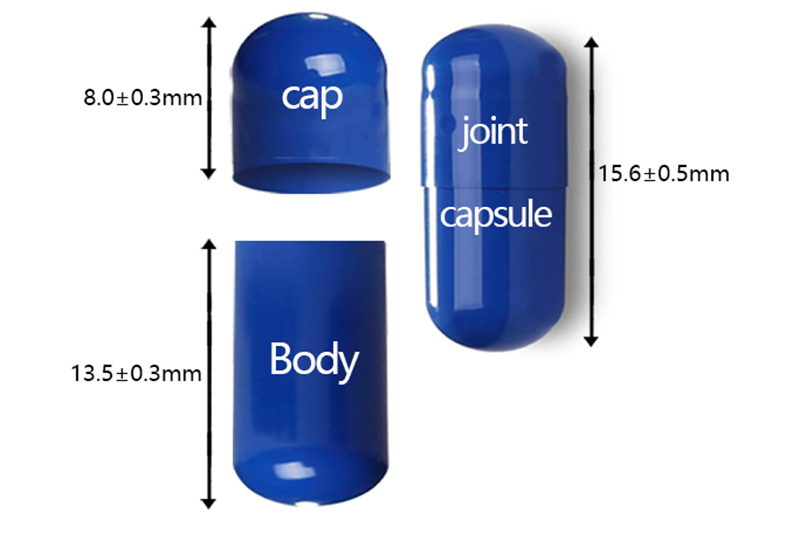

| Cap length(mm) | 11.8±0.3 | 11.0±0.3 | 10.0±0.3 | 9.0±0.3 | 8.0±0.3 | 7.2±0.3 |

| Body length(mm) | 20.8±0.3 | 18.5±0.3 | 16.5±0.3 | 15.5±0.3 | 13.5±0.3 | 12.2±0.3 |

| Well-knit length(mm) | 23.5±0.5 | 21.4±0.5 | 19.1±0.5 | 17.8±0.5 | 15.6±0.5 | 14.2±0.5 |

| Cap diameter(mm) | 8.25±0.05 | 7.71±0.05 | 7.00±0.05 | 6.41±0.05 | 5.90±0.05 | 5.10±0.05 |

| Body diameter(mm) | 7.90±0.05 | 7.39±0.05 | 6.68±0.05 | 6.09±0.05 | 5.60±0.05 | 4.90±0.05 |

| Inner volume(ml) | 0.95 | 0.68 | 0.50 | 0.37 | 0.30 | 0.21 |

| Average weight(mg) | 125±12 | 103±9 | 80±7 | 64±6 | 52±5 | 39±4 |

| Local-pack(pcs) | 80000 | 100000 | 140000 | 170000 | 240000 | 280000 |

| Export-pack(pcs) | 90000 | 110000 | 150000 | 180000 | 250000 | 290000 |

Customers Need Confirm

Customers need to provide samples for index testing and match the specification standard need.

| For matching the color: | Customer needs to provide 50 -- 100pcs capsules sample. |

| For printing the logo: | Customer need to send us HD logo pictures (AI pictures would be better) |

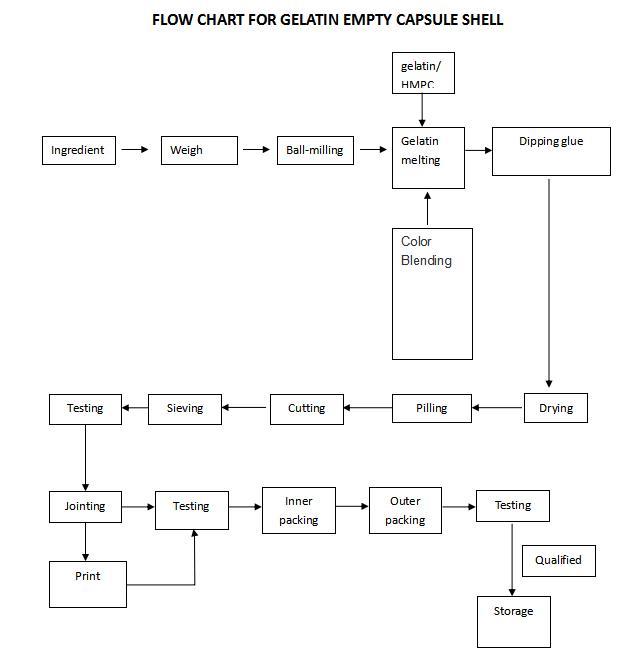

Production Process

Step 1 Gelatin melting

Step 2 Heat Preservation

Step 3 Capsule making

Step 4 Cutting

Step 5 Sieving and Testing

Step 6 Jointing

Step 7 Testing

Step 8 Packing

3-Time Quality Control

On Production Line

Semi-Finished Production

Finished Production

Advantages of Empty Gelatin Capsule

● High product qualification rate 99.9%

● Can be customized color & print per customers' requirement.

● Cooperated with famous factories in our China and out of China.

● Rich experienced workers can produce stable quality.

● Quality can be traceable and once quality approved, we'll keep same raw material to assure the quality uniform and stable.

● Stable quality, 80% senior technicians make sure capsules stable in quality

● Strong production capacity production: 8.5billion/year

Our Certificate

Yasin Capsule VS Other Brand Capsule

|

Physical and Chemical Items |

|

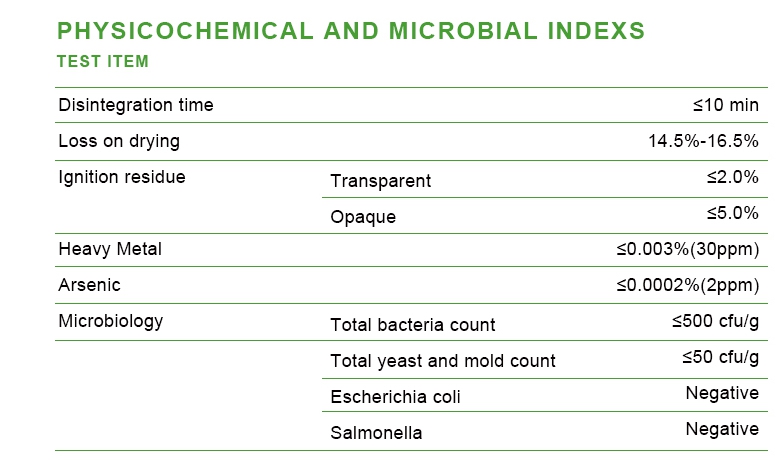

| Test Item | Standard |

| Characteristics | This product is cylinder, by can set close and lock cap and body composed of two qualitative hard and elastic empty capsules. Capsule should be bright and clean, color and luster is uniform, smooth incision, no distortion, no odor. This article is divided into transparent (two does not contain sunscreen), translucent (section contains a sunscreen only), opaque (two contain sunscreen). |

| Identification | Shall be positive |

| Tightness | ≤1 |

| Brittleness degree | ≤5 |

| Disintegration time limit | ≤10.0mins |

| Sulfite | ≤0.01% |

| Chloroethanol | Shall be positive |

| ethylene oxide | ≤0.0001% |

| Drying weightlessness | should be 12.5-17.5% |

| Burning residue | ≤2.0%(transparent),3.0%(semi-transparent),5.0%(opaque) |

| Chromium(ppm) | ≤2 |

| Heavy metal(ppm) | ≤20 |

| Aerobic bacteria count | ≤1000cfu/g |

| Molds and yeast | ≤100cfu/g |

| Escherichia coli | Negative |

| Salmonella | Negative |

Loading Capacity

|

Size |

Package/Carton |

Loading Ability |

|

|

00# |

70000pcs |

147cartons/20ft |

356cartons/40ft |

|

0# |

100000pcs |

147cartons/20ft | 356cartons/40ft |

|

1# |

14000pcs |

147cartons/20ft | 356cartons/40ft |

|

2# |

170000pcs |

147cartons/20ft | 356cartons/40ft |

|

3# |

240000pcs |

147cartons/20ft | 356cartons/40ft |

|

4# |

280000pcs |

147cartons/20ft | 356cartons/40ft |

|

Packing & CBM : 74CM*40CM*60CM |

|||

Packing Details

Packing: Inner packing is one layer of plastic bag + one layer of aluminum foil bag + outer packing is carton packing

Application

Advantage of GELATIN Capsule

1. High Gloss and Bright appearance, easy to swallow with fewer efforts.

2. The disintegration time is relatively shorter than Vegetable ones. ( 6 Min VS 10Min), So it is easier for our bodies to absorb and digest.

3. Perfect qualification rate on filling machines. The proportion of vegetable Capsule turns out to be 99.99% VS Gelatin’s 99.97%. The defective capsules can be ignored basically.

4. Compared with tablets and pills, the gelatin capsule has better bioavailability, as no adhesive is added to stabilize the drugs, so it is more pure and easier for absorption.

5. It is applicable to make sustained release and compound formulations. The drugs are able to be dissolved in fixed time and position in the intestine system.

6. Simple recipe and manufacturing process, Convenient for automatic and industrial mass production.

Empty Capsule Specification

Specification sheet

Size Index

| SizeSpecification |

00# |

0# |

1# |

2# |

3# |

4# |

| Cap length(mm) |

11.8±0.3 |

11.0±0.3 |

10.0±0.3 |

9.0±0.3 |

8.0±0.3 |

7.2±0.3 |

| Body length(mm) |

20.8±0.3 |

18.5±0.3 |

16.5±0.3 |

15.5±0.3 |

13.5±0.3 |

12.2±0.3 |

| Well-knit length(mm) |

23.5±0.5 |

21.4±0.5 |

19.1±0.5 |

17.8±0.5 |

15.6±0.5 |

14.2±0.5 |

| Cap diameter(mm) |

8.25±0.05 |

7.71±0.05 |

7.00±0.05 |

6.41±0.05 |

5.90±0.05 |

5.10±0.05 |

| Body diameter (mm) |

7.90±0.05 |

7.39±0.05 |

6.68±0.05 |

6.09±0.05 |

5.60±0.05 |

4.90±0.05 |

| Inner volume(ml) |

0.95 |

0.68 |

0.50 |

0.37 |

0.30 |

0.21 |

| Average weight (mg) |

125±12 |

103±9 |

80±7 |

64±6 |

52±5 |

39±4 |

| Packing size(pcs) |

80000 |

100000 |

140000 |

170000 |

240000 |

280000 |

Empty Gelatin Capsule

A capsule is an edible package made from gelatin or other suitable material and filled with a drug(s) to produce a unit dosage, mainly for oral use. Our gelatin capsule is made from bovine bone.

Hard Gelatin Capsule is composed of two pieces in the form of cylinders closed at one end. The shorter piece, called the “cap”, fits over the open end of the longer piece, called the “body”.

Gelatin is the most commonly used material for capsule manufacturing.

production process

quality system

1. We conduct strict control of raw material & products quality. The raw material of gelatin capsule is based on healthy bovine bone. The whole material quality system is guaranteed, being paid attention in details to guarantee quality evenness.

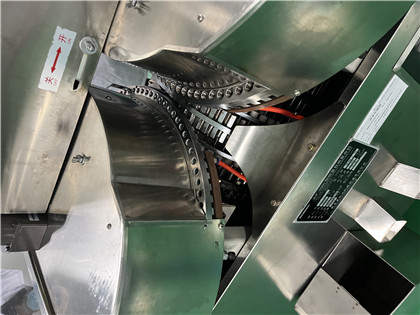

2. The whole manufacturing process is implemented with great dedication and full responsibility. The world-class automatic facilities are used skillfully by Competent Personnel, establishing an efficient and orderly GMP management system. Here displayed some core advanced equipment conforming to the highest pharmaceutical standard:

World-class Aseptic Room Facility

Cutting-edge Manufacturing Machines

Well-documented Monitoring System

Stringent Hygiene Standards

Climate and Humidity Diagnostic Equipment

3. The quality assurance is absolutely trustable. Regular and planned hands-on workshops addressing the training needs enable us to maintain consistency. So no defective capsules are produced under such thorough inspection and continuous monitoring, as each step is cautiously reviewed in every management to continue suitability.

storage & packing condition

Storage precautions:

1. Keep the Inventory temperature at 10 to 25 ℃; Relative humidity remains at 35-65%. 5 Year’s storage guarantee.

2. The capsules are supposed to be kept in a clean, dry and ventilated warehouse, and are not allowed to be exposed to strong sunlight or humid environment. Besides, as they are too light to be fragile, the heavy cargos should not pile up.

Packaging requirements:

1. Medical low-density polyethylene bags are used for inner packaging.

2. To prevent damage and moisture, the outer packing uses 5-ply Kraft paper dual corrugated structure packing box.

3. Two outer packing specifications: 550 x 440 x 740 mm or 390 x 590 x 720mm.